Getting to Know BLC Manufacturing Plant

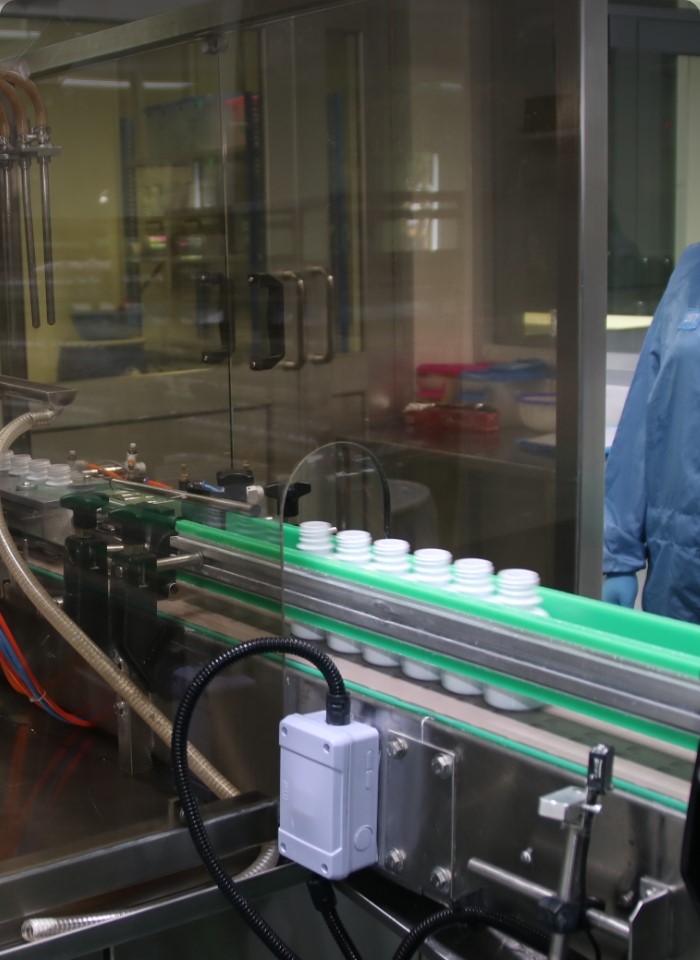

Production Line

From an early factory dedicated to the production of generic drugs, the Company has continued developing its manufacturing capabilities, enabling the factory to produce a broad spectrum of health products including modern medicines, generic and new generic drugs, herbal medicine, cosmetics, dietary supplements among many other things.

The Company operates business with emphasis on safety in all facets to minimize its environmental impacts. Top priority is given to quality control to ensure standard and consistency in alignment with the requirements and good manufacturing practices in three main areas: place, person, and machine.

Place

- The production facility boasts a closed system design with a closed-loop HAVAC Clean Room Class 100000 system to ensure a hygienic production process.

- The production facility features access control systems to reduce the risk of contamination from dirt, animals, and insects.

- Efficient HVAC (Heating Ventilation Air Condition) systems of high standards are implemented to maintain the quality of products throughout the process.

- A systematic and continuous workflow of the work is laid out to ensure production efficiency and prevent contamination. As well, to prevent cross-contamination, the pressure in the production room is properly controlled in accordance with the prescribed standards.

Person

- An adequate number of qualified and experienced personnel are recruited.

- Personnel undergo training to increase knowledge and understanding before starting their work and will constantly be provided with further training.

- Production line operators must behave properly such as wearing special gowns in the cleanroom to prevent cross-contamination to products.

- Personnel must fully understand their duties as specified in the job descriptions and be aware of the requirements and good manufacturing practices with concern for quality.

Machine

The cutting-edge production machinery with qualification and suitability for the manufacturing process can be described as follows:

- Design Qualification is the documented verification that the proposed design of the facilities, systems, and equipment is suitable for the intended purposes.

- Installation Qualification is the documented verification that the proposed design of facilities and equipment has been installed or configured according to standards set by the manufacturer.

- Operational Qualification is the documented verification that the proposed design of the facilities and equipment which has been installed perform as defined throughout.

- Performance Qualification is the documented verification that the proposed design of facilities and equipment that has been connected are capable of performing effectively and repeating the activities of the process according to the pre-approved specifications of the products.

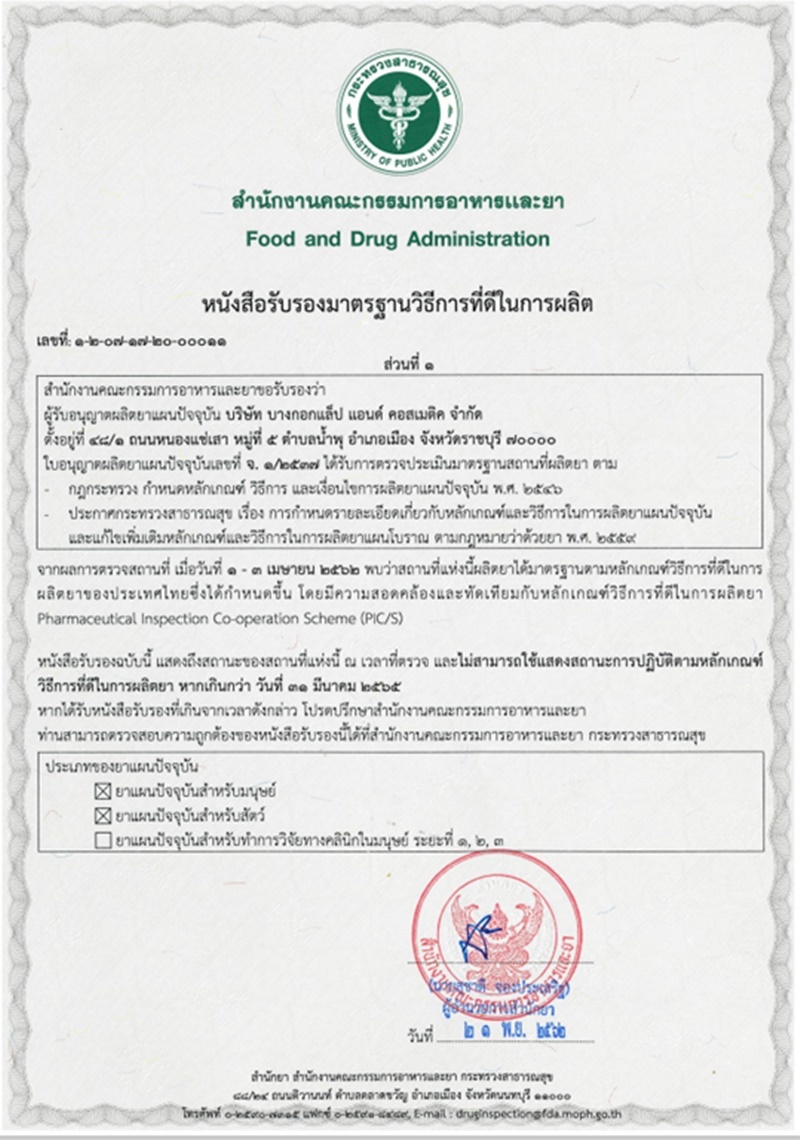

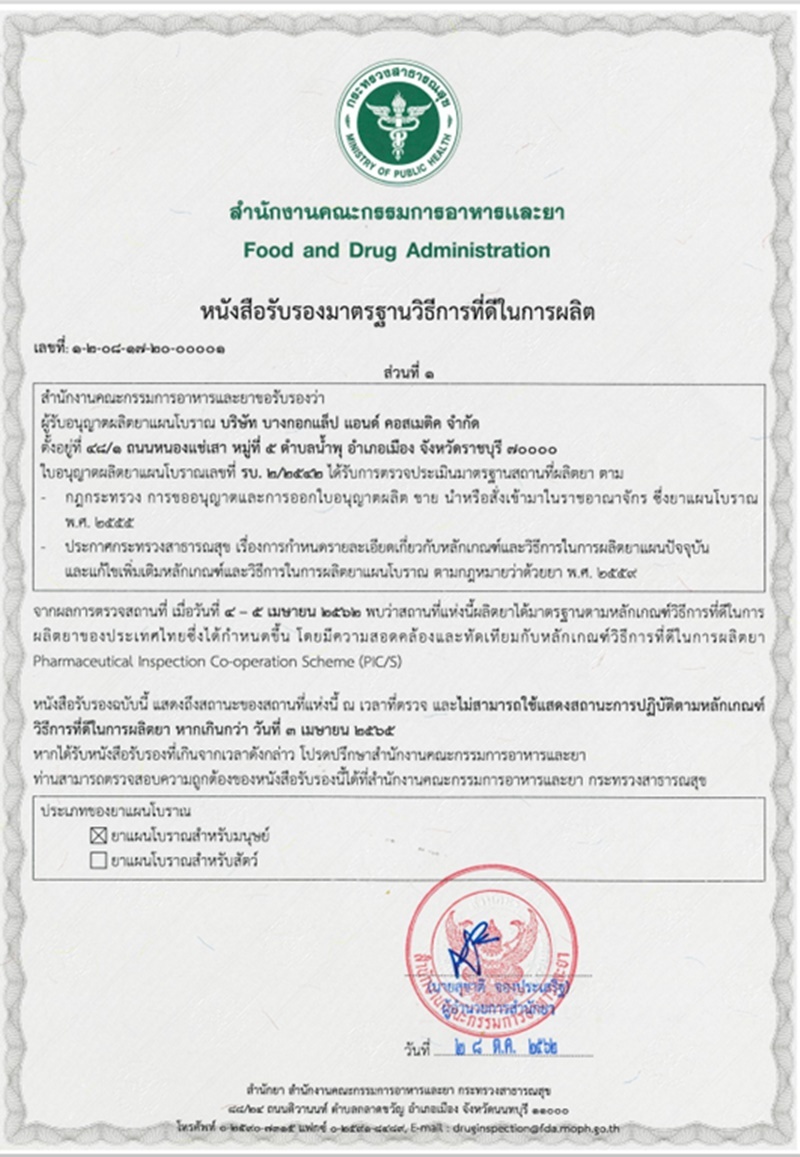

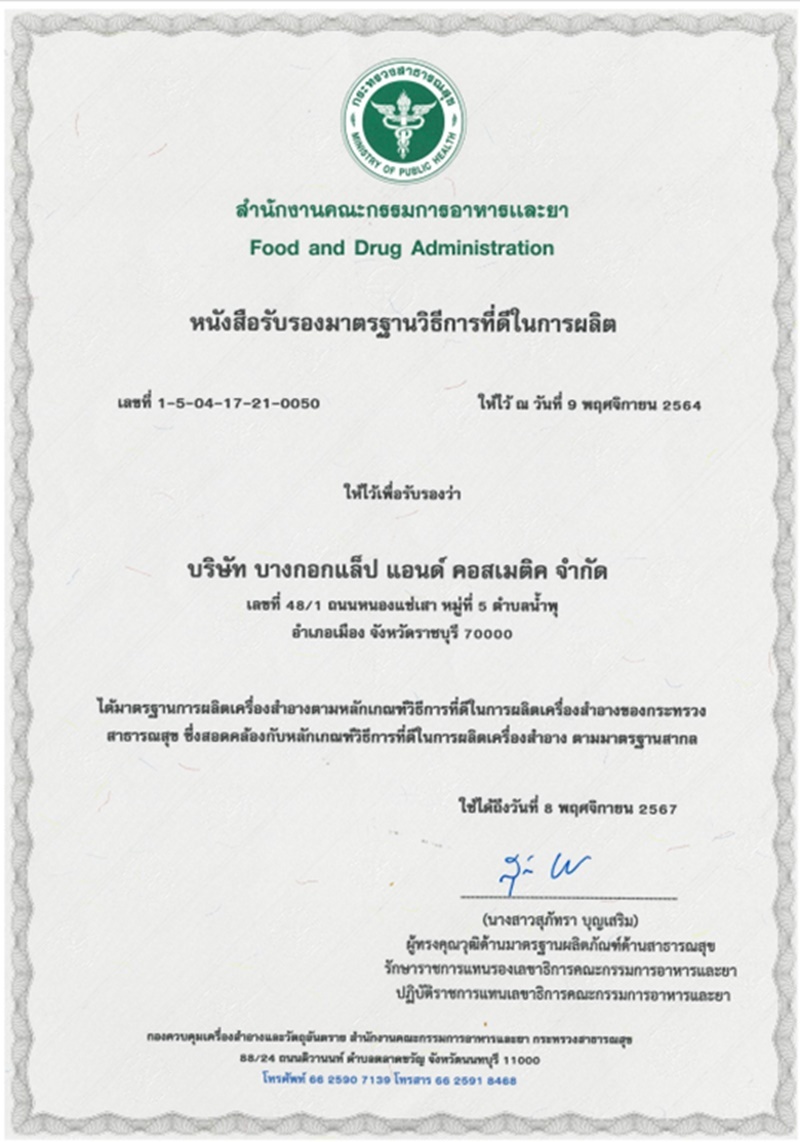

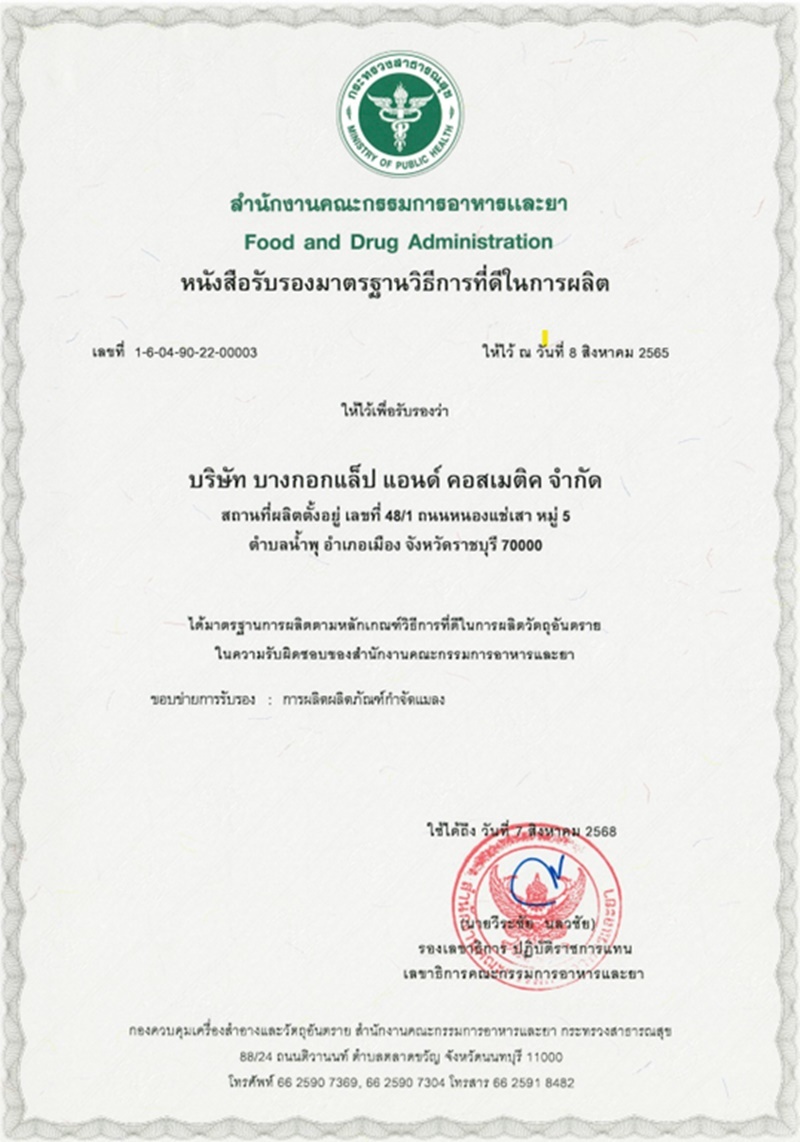

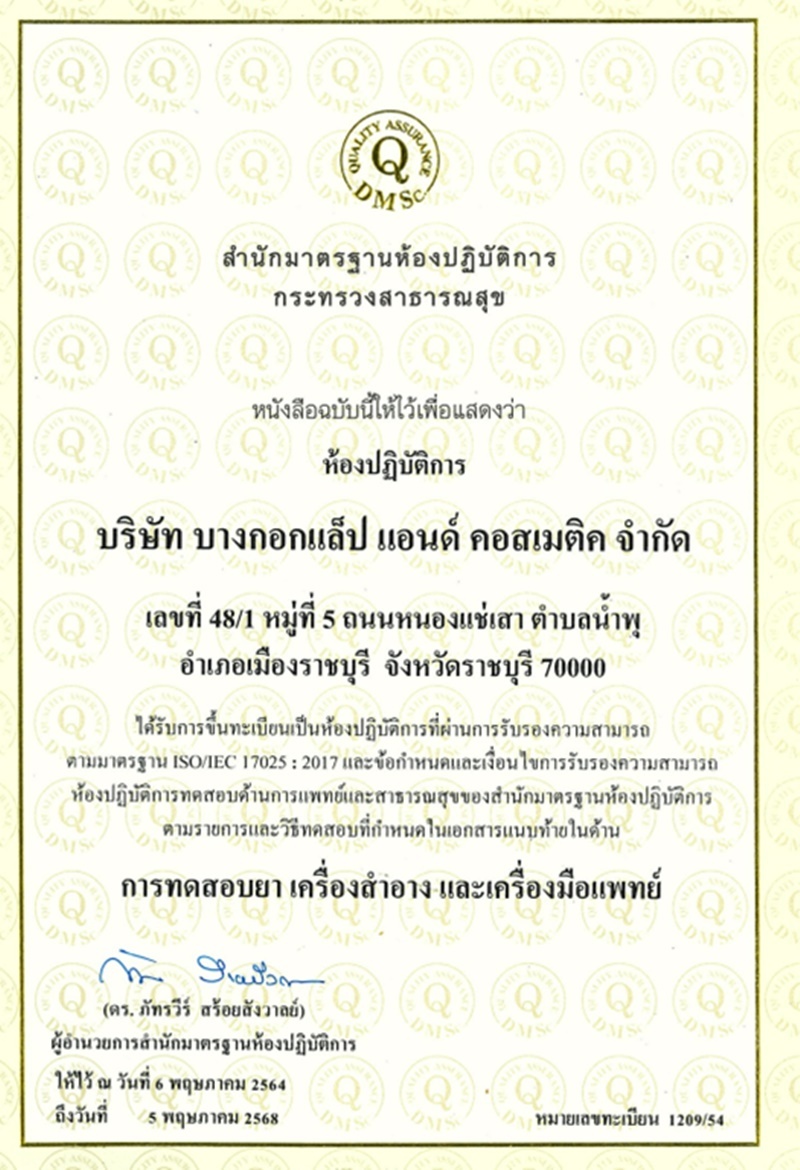

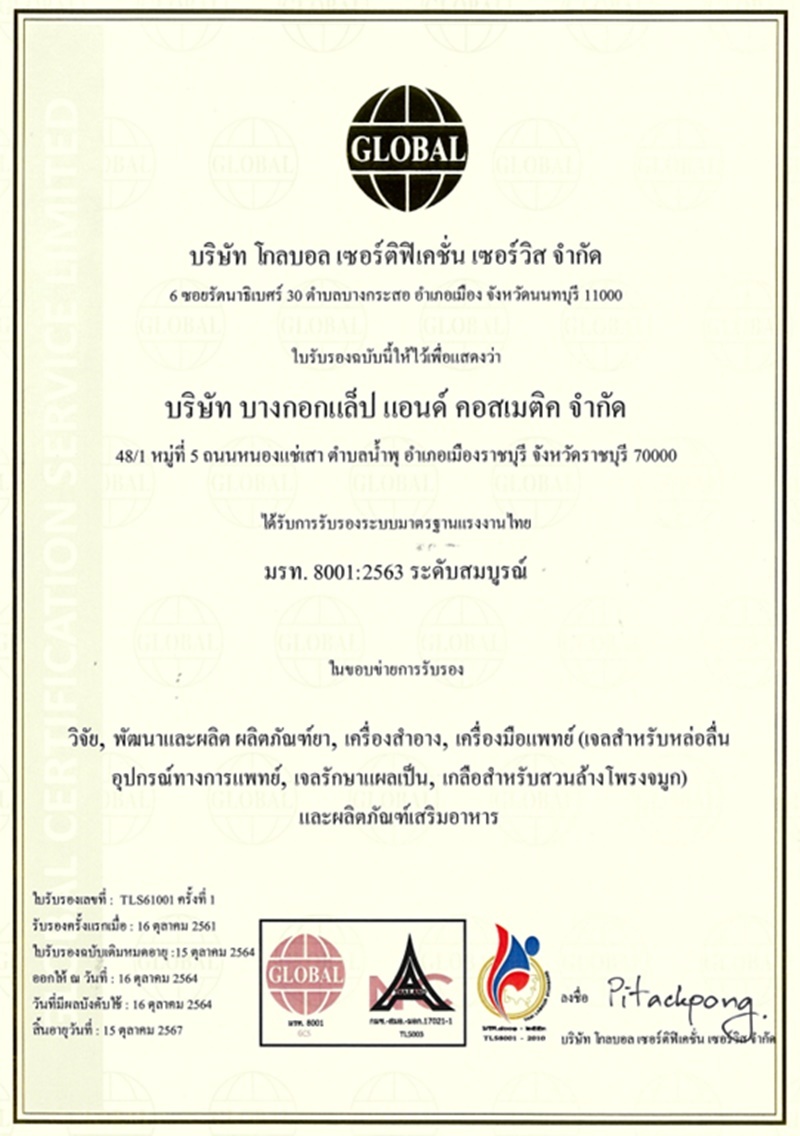

Manufacturing Operations Certificates Achieved by BLC

BLC Research Center

In tune with the policy to develop a stable business based on the body of knowledge and innovation, the Company has established BLC Research Center to provide solid foundations for driving the development of innovations and technologies for the Company’s products. The Center is also designed to accommodate the transfer of technology from research agencies, both state and private, such as the National Research Council of Thailand, the Thailand Research Fund, the National Innovation Agency, the Agricultural Research Development Agency (Public Organization), Thailand Center of Excellence for Life Sciences (Public Organization), and pharmaceutical faculties at multiple universities in pursuit of commercializing the research. The focus is on integrating Thai local wisdom and research work into the development of herbal products through a science-based production process, using state-of-the-art technology to increase competitiveness and create sustainable business growth.

BLC Research Center

is located within the premises of the Company's manufacturing facilities. To encompass all aspects of the research efforts, the Research Center comprises the following 3 departments:

Research Administration Department

is dedicated to screening know-how to elevate research work as well as contacting and coordinating with researchers from various institutes to seek collaboration in development and research in multiple areas.

Research I Department

is responsible for the research, design, and development of drug formulations for generic drugs and new generic drugs.

Research II Department

is involved with research and development of herbs to fully utilize herbs in an effective and standard manner. The Department is also tasked with the research and development of cosmetics and dietary supplements.

Laboratories

Laboratories have played a key role in controlling the quality of products and the continued success of Bangkok Lab & Cosmetic Public Company Limited since its founding.

The Company has stressed the importance of designing each laboratory to enable the convenient and safe performance of functions and minimize environmental impacts. The labs also provide controlled conditions appropriate for each testing condition to ensure precision and reliability.

The Company’s laboratories are equipped with a wide variety of sophisticated devices such as Chromatography (HPLC), Fourier Transform Infrared Spectroscopy (FTIR), Inductively Couple Plasma / Optically Emission Spectroscopy (ICP/OES), High Performance Thin Layer Chromatography (HTPLC), UV Spectrophotometry among many others. To ensure standards, all instruments and devices are regularly calibrated and checked for their proper functioning according to the defined maintenance periods by the internal or external agencies, resulting in accurate and precise data. Apart from the equipment, the Company gives top priority to lab operators including pharmacists and scientists in different fields, who have undergone training and skills tests provided by domestic and overseas institutions, as well as possessing many years of experience and high expertise.

The laboratory

of Bangkok Lab & Cosmetic Public Company Limited comprises 5 divisions which operate under the following quality management system: